Condition Monitoring BlogVibration Analysis, Thermography Inspection, Oil Analysis, Motor Current Signature Analysis, Ultrasonic EvaluationUpdate Your KnowledgePredictive Maintenance, Reliability Programs, Condition Based Maintenance, Precision Maintenance, Dynamic Balancing, Machinery Alignment Previous Next Precision Shaft Alignment Alignment is an important part of a successful proactive maintenance program for all rotating shafts. It is a good practice to have …

Monthly Archives: May 2019

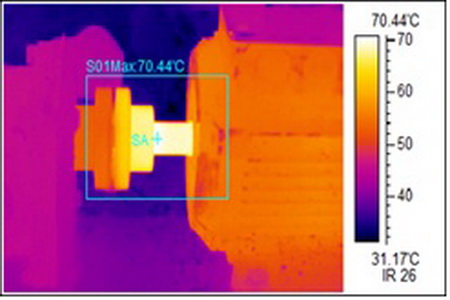

Thermography Inspection for Misalignment Detection

Condition Monitoring BlogVibration Analysis, Thermography Inspection, Oil Analysis, Motor Current Signature Analysis, Ultrasonic EvaluationUpdate Your KnowledgePredictive Maintenance, Reliability Programs, Condition Based Maintenance, Precision Maintenance, Dynamic Balancing, Machinery Alignment Previous Next Thermography Inspection for Misalignment Detection When misalignment occurs, it cause extra load on the coupling, its components and shaft. This usually results in temperature increasing …

Continue reading “Thermography Inspection for Misalignment Detection”

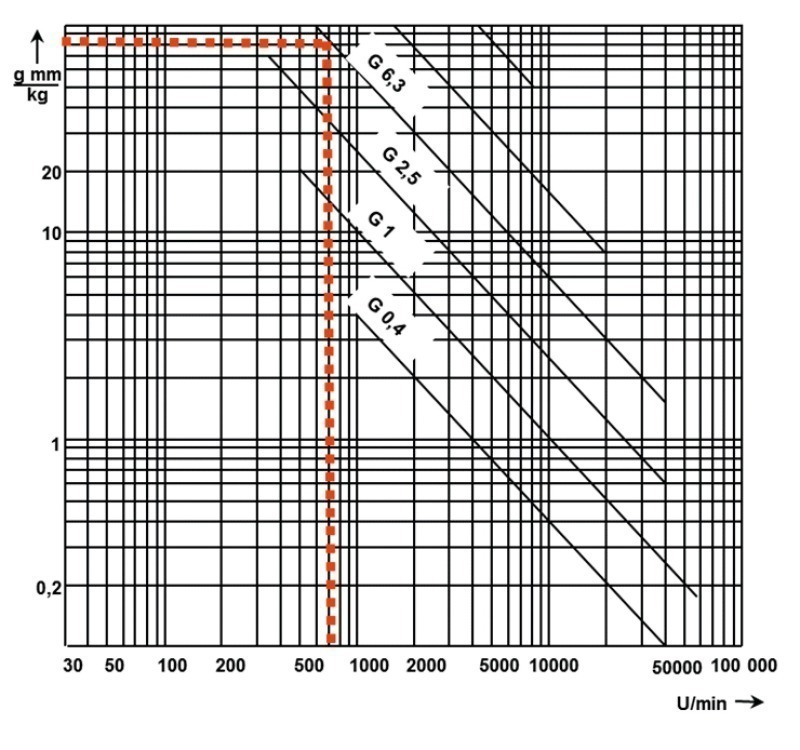

ISO 1940 for Dynamic Balancing

Condition Monitoring BlogVibration Analysis, Thermography Inspection, Oil Analysis, Motor Current Signature Analysis, Ultrasonic EvaluationUpdate Your KnowledgePredictive Maintenance, Reliability Programs, Condition Based Maintenance, Precision Maintenance, Dynamic Balancing, Machinery Alignment Previous Next ISO 1940 for Dynamic Balancing ISO 1940 provides a criteria for evaluating the residual unbalance in rotors. There are several classes of allowable residual unbalance …

The Importance of Correct Oil Sampling for Machinery Oil Analysis

Condition Monitoring BlogVibration Analysis, Thermography Inspection, Oil Analysis, Motor Current Signature Analysis, Ultrasonic EvaluationUpdate Your KnowledgePredictive Maintenance, Reliability Programs, Condition Based Maintenance, Precision Maintenance, Dynamic Balancing, Machinery Alignment Previous Next The Importance of Correct Oil Sampling for Machinery Oil Analysis Oil sampling is one of the most important parts of any oil analysis program. In …

Continue reading “The Importance of Correct Oil Sampling for Machinery Oil Analysis”

ISO 13373: an Important Reference for any Vibration Monitoring Program

Condition Monitoring BlogVibration Analysis, Thermography Inspection, Oil Analysis, Motor Current Signature Analysis, Ultrasonic EvaluationUpdate Your KnowledgePredictive Maintenance, Reliability Programs, Condition Based Maintenance, Precision Maintenance, Dynamic Balancing, Machinery Alignment Previous Next ISO 13373-1: an Important Reference for any Vibration Monitoring Program ISO 13373-1 provides very helpful instructions for developing and implementing an effective vibration monitoring program. …

Continue reading “ISO 13373: an Important Reference for any Vibration Monitoring Program”