Condition Monitoring ServicesJust by One Call, We Are Near YouReliability Improvement ServicesPrecision MaintenanceDynamic Balancing, Machinery AlignmentVibration Analysis ServicesRotating Machinery Fault Diagnosis, Routine Vibration Monitoring, Advanced Vibration TestingOnline Vibration Monitoring (Wireless)Click Here

Previous

Next

Our Services

Approximately half of all operating costs in most processing and manufacturing operations can be attributed to maintenance. This is ample motivation for studying any activity that can potentially lower these costs. Machine condition monitoring and fault diagnostics is one of these activities.

Maintenance decisions are costly

The risk and consequences of maintenance decisions are greater than the design decisions and purchase decisions, because maintenance decisions are made when the equipment is needed for production and time is of the essence.

The cost of maintain a machine over its lifetime is greater than the initial purchase price, especially if energy consumption is considered. Maintenance is a profit centre – able to add dollars to the bottom-line profit by controlling the expense of parts, labor, and unnecessary machine replacements. It is a hidden gold mine within every company.

The Value of Predictive Maintenance (PdM)

Predictive Maintenance (PdM) is usually thought of as the use of condition monitoring technologies to detect machinery faults at an early stage, allowing planned corrective maintenance on an as-needed basis. For more information, click on below button:

Read more about Predictive Maintenance

Our Predictive Maintenance and Condition Monitoring Solutions:

Our predictive maintenance solution opens up innovative new possibilities for companies to ensure that high quality data is acquired and properly analyzed to permit the reliable diagnosis and prognosis of machinery dynamic behavior:

- VibeLube has deep knowledge and experience in setting up predictive condition monitoring program for small to large size plants.

- VibeLube utilizes state-of-the-art four channel vibration data collector / analyzer. This emphasizes proven accuracy and consistency of collected data from rotating equipment along with more collected data in shorter time.

- VibeLube technicians perform route based data collection monthly, by monthly, or quarterly depending on the criticality of the equipment

- VibeLube techniciens apply permanent mounting pads for vibration sensors which enhances early detection of high frequency signals with very low amplitudes.

- VibeLube utilizes triaxial sensor (accelerometer) as standard tool in PDM route collection.

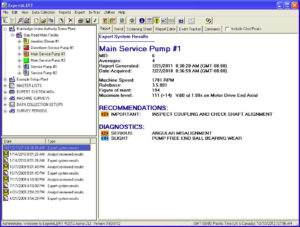

- VibeLube data collector utilizes the most advanced analyzing software in the market. This means all collected vibration data will be analyzed by software right after data collection of each machine. Therefore vibeLube system analyzes and reports the machine condition in spot. On the other hand, the collected data in the field can be sent to a web portal through internet for quick and in depth vibration analysis.

- In VibeLube, analyzing and reporting are performed by experienced certified level III vibration analyst. Therefore in conjugation with instrumentation and procedures, our reports are more accurate and reliable than competitors. This brings a peace of mind for our clients.

- In VibeLube all clients have access to the WATCHMAN Reliability Portal which provides view-level access to plant’s machine condition analysis program database through any modern web browser, from any location; Enterprise/Plant/Area program statistics, machine detailed analysis and health history and the ability to print machine condition analysis reports. Machine health information is widely available to all decision makers in your company. The portal web page and report content are updated in real time as VibeLube’s vibration expert completes his analysis on machine data.