Vibration Analysis and Fault DiagnosisAdvanced Vibration Analysis and TestingModal Analysis, ODS Analysis, Motion Amplification, Cross Channel Analysis, Natural Frequency Testing

Previous

Next

Vibration Analysis Services

Vibration Analysis refers to the process of measuring the vibration levels and frequencies of rotating machinery (Industrial/Commercial) and using that information to determine the “Health” of the machine and its components. Vibration Analysis (VA), applied in an industrial or maintenance environment aims to reduce maintenance costs and equipment downtime by detecting equipment faults. When a problem does appear on a piece of equipment, it generally falls under the jurisdiction of the machinery diagnostician/vibration Analyst to resolve the difficulty and recommended an appropriate course of corrective action.

These individuals must be familiar with problem solving techniques and proven methodology for correcting the machinery malfunction. Clearly, the diagnostician must be qualified in many technical disciplines. The basic areas of expertise include knowledge of machinery, knowledge of physical behavior, plus knowledge of instrumentation. Competence in these three areas is only achieved by a combination of knowledge and field experience. At VibeLube, we deliver this level of competency to our clients.

What services does VibeLube provide?

What services does VibeLube provide? VibeLube provides broad vibration analysis services including:

Diagnosis / Troubleshooting / Root Cause Analysis

-

- Any abnormal noise, vibration, temperature, pressure and current draw are indication of a problem or defect in machine components. If left unattended, the defect can progress to a failure and costly repairs. On-site mechanical inspection and hands on examination is a significant part of any machinery diagnosis. Vibration analyst collects vibration data as well as other parameters and performs analysis for detecting defect(s) followed by corrective actions.

- Unbalance, misalignment, incorrect belt tension, poor lubrication practices, incorrect machine operation, and resonance are common root causes of failures in rotating machinery, however many others exist. Whenever the vibration analyst detects a fault in the machine, he or she should always attempt to determine the root cause. Once the root cause is identified measures should be taken so that root cause is eliminated. It is clever to be able to detect a bearingdefect, but it is not very clever if the same bearing exhibits the same fault condition just months later. The vibration analyst will need to determine the most appropriate action that he or she can take at their place of work to avoid a repeat of the fault.

Resonance occurs when a machine generates vibration at a frequency close to a natural frequency of

the rotor or structure. Resonance greatly amplifies the vibration amplitude; the high vibration

amplitude reduces the life of the bearings and the machine structure. The vibration analyst can get

involved in two ways:

- First the vibration analyst can identify the source of vibration that is exciting the natural frequency and seek to reduce that vibration amplitude. For example, if there is unbalance which is exciting the natural frequency then one solution is to simply balance the machine.

- The second way that the vibration analyst can help is to perform tests that identify the natural frequencies and then propose modifications to the structure so that the natural frequencies no longer correspond to the frequencies being generated by the machine. The most common situation is where the running speed of the machine corresponds with the natural frequency, however other sources of vibration such as the pump vane rate, blade passing frequencies and other can also excite natural frequencies. It may be necessary to increase the stiffness of the structure to increase the natural frequency so that it is no longer excited by the vibration generated by the machine.

Commissioning / Acceptance Testing

There is often an assumption that components, lubricants and the machines themselves are in perfect condition when they are purchased. Sadly, this is not always the case. Bearings may not be transported or stored correctly and may suffer from false-brinelling. Lubricants may not meet cleanliness standards.Rotating machinery may suffer from resonance and other conditions when operated under normal conditions. Too often rotating machinery are not designed with energy efficiency and reliability in mind; instead they are designed with purchase cost in mind. Acceptance testing provides a way to test that machines and components are in good condition before they are installed in the plant. Acceptance testing puts pressure on the supplier to make sure they are delivering the highest quality products. Acceptance testing guidelines can include specifications on several parameters, but from the vibration analyst’s perspective the key standard is to set vibration limits that may not be exceeded. Tests may be performed at the OEMs workshop or after being installed on-site. It is important the conditions for the test are clearly specified, including RPM, load, and mounting. Acceptance testing should not only be performed on new equipment, it should be performed when repair and overhaul work is performed. This can include motor rewinds, rotor balancing, and pump or compressor rebuilds.

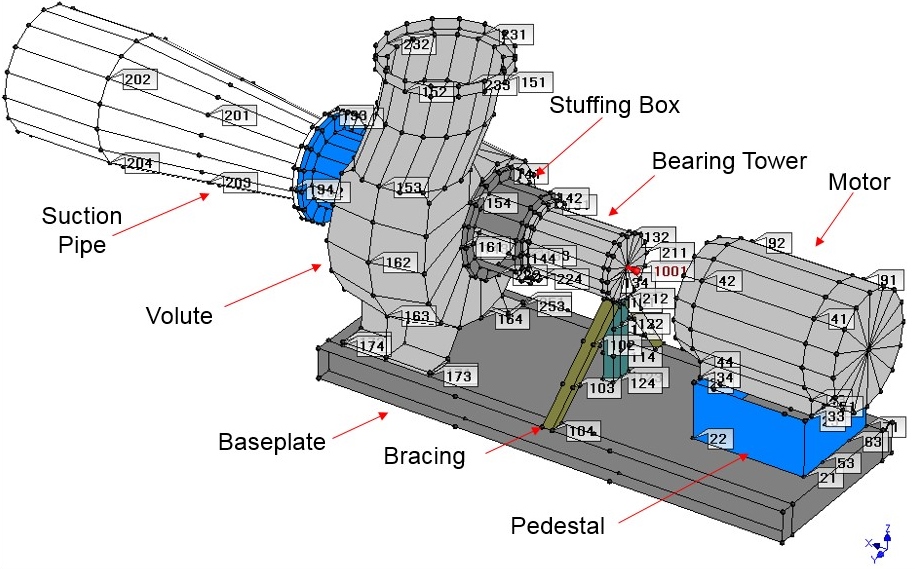

ODS and Modal Analysis are two advanced vibration testing that are used in fault diagnosis of complex vibration problems.

ODS analysis are used in evaluating:

-

- Structural vibration problems

- Complex and usually chronic vibration problems that can not be diagnosed with simple FFT analysis

- Resonance

- Looseness

Modal analysis is used for evaluating resonance problems and helps finding practical solution for them. This is especially useful for design related issues that affect machine reliability if left unsolved.

Condition Monitoring (Predictive Maintenance)

Condition Monitoring (CM) which is often referred to as Predictive Maintenance (PdM) is monitoring of

parameters such as vibration, noise, temperature, pressure and current on machine components for

tracking changes and verifying its condition. Monitoring can be done periodically or continuously.

Vibration Analysis as a key component of a CM/PdM program will always be required, even when the

best reliability improvement programs are well-established.

VibeLube is a premier provider of predictive machine condition monitoring and analysis services that

align with customers’ high standards for reliability, availability and uptime. VibeLub’s Reliability Services

utilize flexible deployment models, proven diagnostic software and unmatched analytical expertise to

deliver sustainable, scalable and cost-effective condition-based maintenance programs. The company’s

bundled solutions enable customers to choose comprehensive, proven programs that ensure asset

availability and maximize productivity.

Dynamic Balancing / Alignment (Precision Maintenance)

Mass Imbalance, as well as Shafts Miss-Alignment are the most common causes of high vibrations in

rotating equipment. Balancing reduces rotating forces which can damage bearings and the machine

structure. Likewise shaft alignment reduces the stress on bearings, couplings, and the shaft itself. For

smooth & safe operation of any rotating equipment, it is recommended to check vibrations and perform

balancing & alignment, particularly when they are new installed machines or newly repaired or

overhauled.

VibeLube offers expert field balancing, alignment and vibration analysis services. We bring extensive

experience along with the most advanced portable instrument and software to your plant to perform an

excellent job.

At VibeLube we don’t just assist our clients in reduction of maintenance and operating costs, we get involved with reliability improvement.

Benefits of VibeLube’s PdM Vibration Analysis Program

When comparing our capabilities and proposed solution to that of competitors, the benefits of choosing VibeLube is:

- VibeLube has deep knowledge and experience in setting up predictive vibration analysis program for small to large size plants and facilities and delivers comprehensive, actionable machine health reports aimed at reducing unplanned downtime and ensuring maintenance is performed in the most efficient manner.

- Our predictive maintenance solution opens up innovative new possibilities to ensure that high quality data is acquired and properly analyzed to permit the reliable diagnosis and prognosis of machinery dynamic behavior.

- VibeLube utilizes state-of-the-art four channel vibration data collector / analyzer in the market.

- VibeLube uses tri-axial sensor (accelerometer) as standard tool in PdM route collection. A tri-axial accelerometer with mounting pad is the most efficient method available to collect a complete set of vibration data in three mutually perpendicular directions. This method of data collection for portable, periodic data collection offers the following advantages:

FAST – Collect vibration data in all three directions in one step instead of moving a single axis accelerometer from one location to the next.

COMPLETE DATA SET – Besides collecting data in three directions all of our portable data collectors support the collection of two frequency ranges, typically, low range (10 x machine speed) and high range (100 x machine speed).

REPEATABLE – The use of a permanent mounting pad affixed to each measurement location (e.g. inboard & outboard bearing housing) for mounting the tri-axial accelerometer insures repeatable data that can be accurately trended over time. In addition it enhances the quality of data collection and early defect signals’ detection.

- Our prices are very reasonable and affordable.

- We perform emergency diagnosis on any machine outside of the regular testing cycle with a guaranteed 24-hour turnaround.

- We have an in-house safety program. Our Job Safety Analysis (JSA) form is filled out at all job sites to capture the current safety issues at the location (for example, loud noise, slip & trip, hot surfaces, etc.)